Inzicht in Vlambeschermers voor solderen: een uitgebreide handleiding

Bij het werken met solderen staan veiligheid en precisie voorop. Een vlambeschermer is een essentieel hulpmiddel dat is ontworpen om de veiligheid en efficiëntie tijdens soldeerwerkzaamheden te verbeteren. In deze gids wordt dieper ingegaan op wat vlambeschermers zijn, wat hun prestatiekenmerken zijn en hoe ze in verschillende scenario's worden gebruikt.

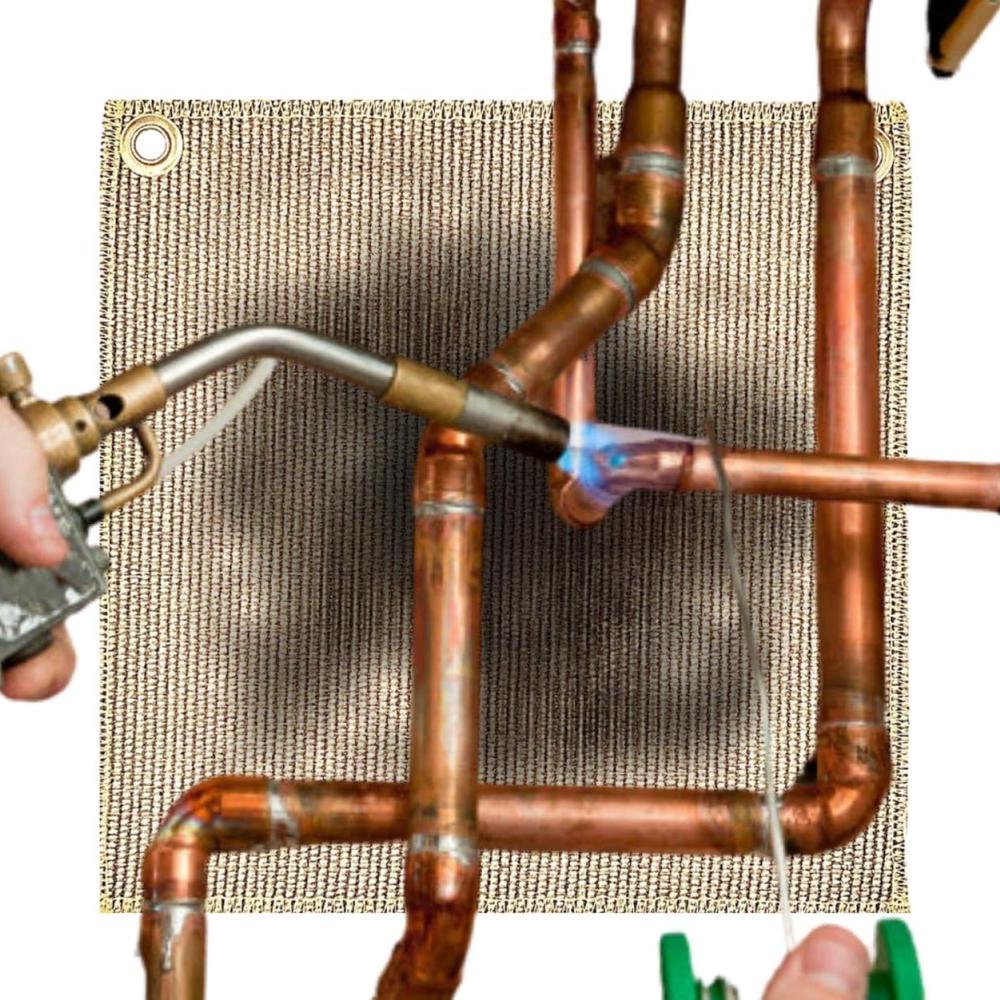

Een vlambeschermer is een gespecialiseerd accessoire dat bij het solderen wordt gebruikt om gevoelige componenten, oppervlakken of materialen te beschermen tegen de intense hitte en mogelijke vlamgevaren die tijdens het solderen ontstaan. Deze beschermers zijn doorgaans gemaakt van hittebestendige materialen, zoals glasvezel of met siliconen gecoate stoffen, die de warmte effectief blokkeren of afvoeren.

Hittebestendigheid: Vlambeschermers zijn ontworpen om hoge temperaturen te weerstaan, vaak tot 1.000 °C (1.832 °F), zodat ze tijdens het solderen niet worden afgebroken of vlam vatten.

Vlamvertraging: Ze zijn behandeld met vlamvertragende chemicaliën, die het risico op ontsteking minimaliseren en de verspreiding van vlammen voorkomen.

Duurzaamheid: Vlambeschermers zijn gemaakt van robuuste materialen en zijn ontworpen voor herhaald gebruik, waarbij ze hun beschermende eigenschappen in de loop van de tijd behouden.

Flexibiliteit en veelzijdigheid: deze beschermers zijn er in verschillende vormen, zoals matten, schilden en hoezen, waardoor maatwerk mogelijk is op basis van de specifieke vereisten van de soldeertaak.

Elektronische productie: Bij de assemblage van elektronica zijn vlambeschermers cruciaal voor het beschermen van printplaten (PCB's) en nabijgelegen componenten tegen onbedoelde blootstelling aan hitte. Tijdens het solderen van kwetsbare microchips kan bijvoorbeeld een vlambeschermer worden gebruikt om aangrenzende componenten af te schermen die door overmatige hitte beschadigd zouden kunnen raken.

Sieraden maken: Juweliers gebruiken vlambeschermers om edelstenen en andere hittegevoelige materialen te beschermen tegen schade tijdens soldeerprocessen. Een vlambestendige mat onder het stuk helpt oververhitting te voorkomen en beschermt het werkoppervlak.

Autoreparatie: Bij autoreparatie worden vlambeschermers gebruikt om kabelbomen, plastic onderdelen en brandstofleidingen te beschermen tegen de hitte van soldeerwerkzaamheden. Dit is vooral belangrijk bij het werken in besloten ruimtes waar warmte gemakkelijk naar onbedoelde gebieden kan worden overgebracht.

Metaalbewerking: Vlambeschermers worden gebruikt in de metaalbewerking om omliggende gebieden te beschermen tegen de intense hitte die wordt geproduceerd tijdens het solderen of lassen. Bij het solderen van metalen onderdelen kan bijvoorbeeld een hittebestendig schild worden geplaatst om aangrenzende oppervlakken te beschermen en hittegerelateerde schade te voorkomen.

John, een elektronicatechnicus, vertelt:

"Het gebruik van een vlambeschermer is een essentieel onderdeel geworden van mijn soldeeropstelling. Het beschermt niet alleen mijn kwetsbare componenten tegen hitte, maar helpt ook bij het handhaven van een schone en veilige werkomgeving. De hittebestendige mat die ik gebruik is duurzaam en heeft mij gered van veel potentiële ongelukken."

Emily, een juwelier, commentaar:

"Bij het maken van sieraden is precisie essentieel. Met een vlambeschermer kan ik aan ingewikkelde stukken werken zonder bang te zijn dat ik de edelstenen beschadig. De vlambestendige stof die ik gebruik is flexibel en gemakkelijk te hanteren, waardoor het een waardevol hulpmiddel is in mijn werkplaats."

Mike, een automonteur, zegt:

"Het bij de hand hebben van een vlambeschermer bij het solderen van auto-onderdelen is van cruciaal belang. Het zorgt ervoor dat ik niet per ongeluk gevoelige bedrading of nabijgelegen plastic onderdelen beschadig. Het is een eenvoudige maar effectieve manier om de veiligheid en efficiëntie te verbeteren."

Vlambeschermers voor solderenzijn onmisbare hulpmiddelen die kritische bescherming bieden tegen hitte en vlammen. Het gebruik ervan omvat verschillende industrieën, van elektronica en sieraden maken tot autoreparatie en metaalbewerking. Door hun kenmerken en toepassingen te begrijpen, kunnen gebruikers de veiligheid en de precisie verbeteren en de levensduur van hun materialen en componenten garanderen. Of u nu een professionele technicus of een hobbyist bent, het opnemen van een vlambeschermer in uw soldeergereedschapsset is een verstandige investering voor zowel de veiligheid als de effectiviteit.

vorig :

Wat is geweven glasvezel Drop Warp Tape?De volgende :

Wat is een lasdeken van silicadoek?